ABOUT

About

Passion. Performance. Perfection. When you choose Atacama, you choose all three.

Our Shared Passion.

At Atacama, Defenders are our passion, and we suspect they are yours as well. Good news — you’ve come to the right place.

We’ve dedicated significant time to maintaining and repairing these custom Defenders, perfecting the art of full frame-off restoration and customization. As experts in body work, engine, and drivetrain services, we offer a meticulous restoration process that starts with selecting only the best vehicles and ends with the delivery of your fully custom vehicle and a companion book filled with photos documenting the entire restoration process.

Optimizing Performance

The performance-optimization process begins with selecting the right vehicle. At Actacama, we ONLY use authentic Defenders built on Solihull, England. (Please note we do not convert left-hand drive to right-hand drive.) Each of our vehicles undergoes a thorough restoration process, during which all parts are individually disassembled for preparation and painting. While maintaining the vehicle’s classical style and originality, we add touches of modernization, reliability, and comfort, ensuring optimal performance and an adventurous experience each time you drive.

Ensuring Perfection

When you want perfection, you want Atacama. Meticulous is too soft a word to describe our restoration process, which considers each minor detail and uses only the highest quality parts. This process begins with individually disassembling all parts for preparation and painting and ends with a complete and thorough inspection and road test. What’s in between is a full-scale restoration consisting of the following steps:

sourcing

Disassembly

Inspection

Sand blasting and preparation

Body work

Painting

Mechanical rebuild

Upholstery and Interior

Assembly

Inspection, road test and quality control

SOURCING

We start our process with the right vehicles, selecting only unmolested, rust free, and structurally solid vehicles that have passed our extensive verification and inspection process, which includes ensuring that the engine and other mechanical components match original factory records. Only those Defenders that meet all these criteria join our inventory.

DISASSEMBLY

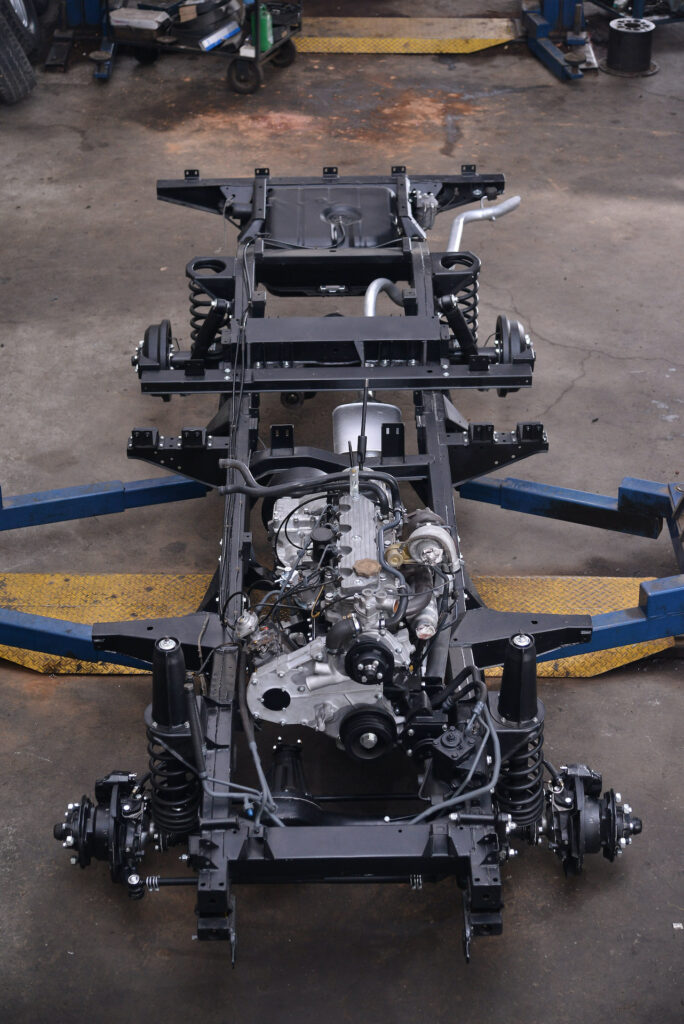

To ensure a flawless rebuild process, we disassemble the entire vehicle down to the bare frame for preparation and inspection.

INSPECTION

We create a solid base for your new build by carefully inspecting the frame, ensuring correct factory alignment according to the manufacturer specifications. We also disassemble axels, gear box, transfer case, and engines for careful inspection during this phase, while procuring primary body parts, including bulkheads, doors, and other components. Throughout the process, we use only the highest quality parts.

SAND BLASTING AND PREPARATION

After inspection, we run the frame through a complete internal cleaning process to remove dirt and debris before we sandblast and prime it. At the same time, we sandblast and prime axel cases, drive shaft, suspension components, and several other parts. We set aside still more parts for zinc plating and hot-dip galvanizing.

BODY WORK

Before priming and painting your new Defender’s body, we carefully inspect it by removing all panels for separate painting and disposing of all parts deemed unfit for use. We’ll replace those parts with new ones and prepare all for painting.

PAINTING

To ensure maximum protection, we paint the frame, axels, cases, housing, drive shaft, and other suspension components individually with a specially selected, high-quality paint. Next, we safeguard the frame from corrosion with a powerful corrosion protection wax applied internally to the frame, which we also apply to all internal body part cavities. Unlike our competition, we don’t tape off and spray our body parts. Instead, we use only premium automotive paint to paint the roof, side panels, doors, and small body parts individually.

MECHANICAL REBUILD

Our goal for the mechanical rebuild is to produce a Defender that is more reliable than when it was new and leaving the factory. We achieve this goal by stripping down all mechanical components and conducting a thorough inspection. We completely disassemble the engine transmission, transfer case, and axles and replace gaskets and seals, as well as all internal components as needed. We also replace all suspension bushings, tie rods, springs, shocks, wheel bearings, seals, clutch master and slave cylinders, brakes components, and other parts. Throughout this process, we use only the highest quality brand components and keep a log of all parts replaced with receipts for customers’ future reference.

UPHOLSTERY AND INTERIOR

With custom stitching and designs available, we develop the interior of your Defender to match your style, adding a touch of comfort, luxury, and class to this classic vehicle. You may wish to use the standard Defender upholstery to maintain the original aesthetic. Or, you may prefer high-quality leather. Whatever you select, you can rest assured that your new Defender will look as stunning as it performs down to all the minor details. We can even wrap the vehicle interior components with leather and chosen design, including the steering wheel, cubby box, dash and door cards if desired. As a last touch, each Defender is equipped with new interior carpet matching the interior design.

ASSEMBLY

During the assembly phase, each of the body panels is installed to ensure perfect alignment using new factory rivets and bolts. We replace all brackets with new or zinc-coat the originals, use a special cavity wax to prevent corrosion, and replace hinges, door seals, window seals, window channels, door locks, and door handles with quality parts.

During this phase, we also resolve the well-known Defender issue of water ingress and protect against corrosion with a special cavity wax.

INSPECTION, ROAD TEST AND QUALITY CONTROL

Before it comes to you, the final step in the process is the most important. We thoroughly and rigorously test the vehicle to ensure quality and reliability using a complete quality control checklist.